Blog

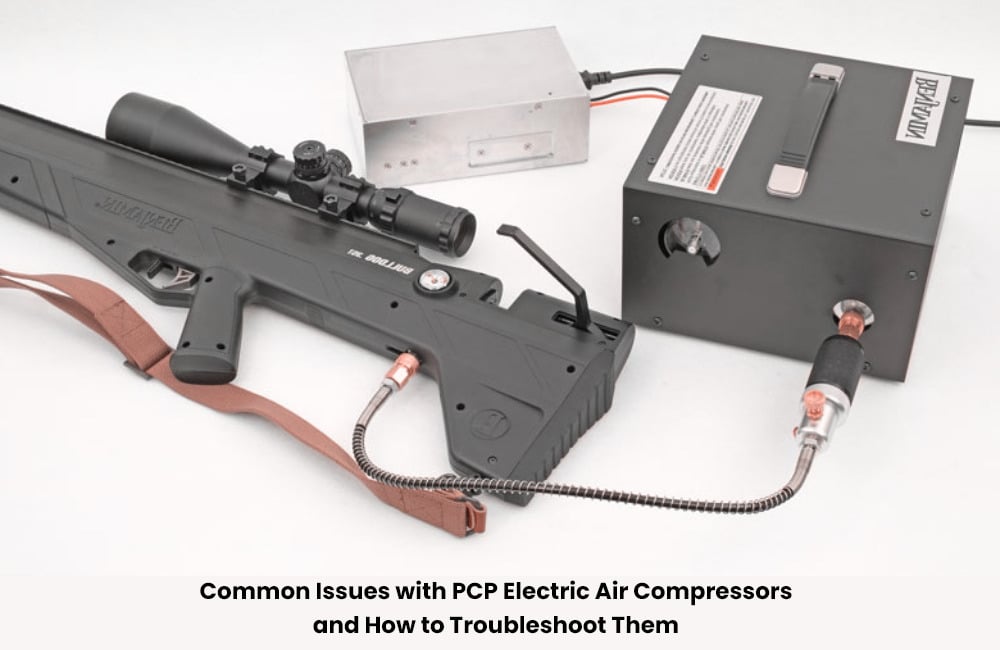

Common Issues with PCP Electric Air Compressors and How to Troubleshoot Them

Are you fed up with your PCP electric air compressor causing you endless problems? Fear not; troubleshooting these problems is easier than you might think. As the saying goes, prevention is better than cure.

Troubleshooting your PCP electric air compressor is not just about fixing existing problems but also preventing them from arising in the first place. This is where the importance of proper and routine maintenance comes in.

By recognizing common issues with your compressor, you can better identify the source of the problem and resolve it quickly. So, let’s dive into the common issues with PCP electric air compressors and discover some troubleshooting tips.

Overheating

Overheating is a critical issue that PCP electric air compressors may face. When it comes to air compressors, overheating may arise due to a variety of reasons. One reason is improper maintenance of the cooling system, or in some cases, the cooling system may be clogged with dust or debris. Another reason that may contribute to overheating is the operating pressure exceeding the maximum limit.

When your air compressor overheats, it could result in some severe problems. For instance, it could lead to damaged components or, even worse, injury to the user. Therefore, it’s critical to address this problem as soon as possible.

Troubleshooting Tips for Addressing Overheating Issues

Overheating can be the bane of any PCP electric air compressor owner. But fear not; there are steps you can take to address this frustrating issue. First, ensure that your compressor is receiving proper ventilation and is not situated in an enclosed area.

Dust and debris may also contribute to overheating, so keep your compressor clean and free of obstruction. If the issue persists, consider purchasing an external heat sink or installing a fan to help dissipate heat. In the end, addressing overheating issues will not only prolong the life of your compressor but will also save you from potential headaches down the road.

Low Pressure

When it comes to PCP electric air compressors, low pressure can be a major issue that can wreak havoc on your equipment. So, what exactly are the potential causes and consequences of low pressure? Well, it could be anything from a clogged air filter to an improperly adjusted regulator.

Whatever the case may be, ignoring the issue could result in failed shots and decreased accuracy, ultimately compromising your overall performance. Fortunately, there are troubleshooting tips you can try to address the problem.

Troubleshooting Tips for Addressing Low-Pressure Issues

If you’re experiencing low-pressure issues with your PCP electric air compressor, don’t fret! There are several troubleshooting tips you can try before seeking professional help. First, check for any air leaks in the hoses and fittings.

Even a small leak can greatly reduce the pressure output. Additionally, make sure the air filter is clean and free of debris. A dirty filter can restrict airflow, leading to low pressure. Lastly, examine the pressure gauge and make sure it is properly calibrated.

By following these troubleshooting tips, you can avoid costly repairs and get back to smoothly operating your PCP electric air compressor.

Noise

When it comes to the world of electric air compressors, excessive noise can be a real buzzkill. Not only can it be a nuisance for those operating the compressor, but it can also be detrimental to anyone within earshot. The potential causes of this issue vary but could include anything from misaligned components to a lack of lubrication.

Whatever the cause may be, the consequences are the same: a headache-inducing racket that can disrupt any job site or workspace. But fear not, as there are solutions available to combat this problem. Whether it be a sound enclosure or vibration pads, investing in noise-reducing accessories can make all the difference.

Troubleshooting Tips for Addressing Noise Issues

While the occasional bump or squeak from your PCP electric air compressor may not cause a major issue, any persistent noise can create a headache-inducing distraction. Fortunately, there are several simple troubleshooting tips you can use to address these noise issues. First, check to make sure all moving parts are properly lubricated.

Dry or rusty components can create unnecessary friction and sound. Additionally, keep an eye on the mounting position of your compressor, as it may require minor adjustments to reduce noise levels. By taking proactive measures and implementing these simple troubleshooting techniques, you can tame those turbulent noise levels and get back to work in a peaceful, distraction-free environment.

Leaks

Air leaks in PCP electric air compressors are a common problem that can cause serious consequences if left unresolved. These leaks can be caused by a variety of factors, such as worn-out seals, loose fittings, or damaged piping. But whatever the cause may be, the outcome is always the same: decreased air pressure, reduced performance, and increased energy consumption.

To make matters worse, air leaks can also lead to the compressor’s motor overheating, which can result in a total breakdown. Fortunately, these issues can be avoided with regular maintenance and quick repair of any leaks detected. So, if you want your PCP electric air compressor to work at optimal levels and avoid costly repairs, it’s crucial to stay vigilant against the dangers of air leaks.

Troubleshooting Tips for Addressing Leak Issues

If you’re experiencing leakage issues with your PCP electric air compressor, don’t fret just yet. There are some practical troubleshooting tips you can use to address these challenges. For starters, you should consider tightening the connections in the compressor. Loose or improperly fitted connections can often cause air leaks, and tightening them can make a significant difference.

Another option is to replace any damaged components that may be responsible for the leaks. By keeping your eye out for physical wear and tear, you can identify faulty parts such as hoses, connectors, or valves. It might not be the simplest of tasks, but it’s certainly feasible with a little know-how and patience.

Don’t let leak issues deflate your spirit – take actionable steps today to fix them and keep your PCP electric air compressor working at optimal levels.

Electrical Issues

Electrical malfunctions in PCP electric air compressors can be frustrating and even dangerous if not addressed properly. Causes of issues range from inadequate wiring to a malfunctioning pressure switch. Ignoring these problems may lead to potential hazards such as electrocution or fire and can even damage the compressor beyond repair.

However, by regularly ensuring that wiring is secure and grounded, monitoring the condition of the pressure switch, and consulting with a professional electrician, if necessary, users can avoid these potentially costly and risky situations.

It’s important to take electrical problems seriously, but don’t let them get you down! Proactively addressing these issues can help ensure that your PCP electric air compressor can continue to serve you for years to come.

Troubleshooting Tips for Addressing Electrical Issues

When your PCP electric air compressor starts acting up, it can be frustrating trying to pinpoint the root of the issue. However, with a bit of knowledge and some troubleshooting tips, you can quickly get back on track and get your air compressor working like new. First and foremost, it’s essential to ensure your power source is stable and reliable.

Additionally, taking the time to inspect all electrical connections and cables carefully is a must. These small parts can wear out over time or become damaged, resulting in the need for a replacement. Another useful tip is to check the fuse or circuit breaker; a blown a fuse is a common culprit behind electrical issues.

Finally, if none of these steps address the problem, it may be wise to contact a professional who can diagnose and solve the issue for you. With these simple and effective tips, you can quickly and easily address any electrical issues with your PCP electric air compressor.

The Final Verdict

As we come to the end of our journey exploring PCP electric air compressors, it’s important to emphasize the key takeaways from our outline. We covered common issues that may arise with these compressors, such as overheating and low pressure, and the troubleshooting tips that can help resolve these problems.

However, it’s vital to remember that proper maintenance is crucial in extending the life and performance of your compressor. By regularly checking filters, oil levels, and other components, you can prevent problems before they even occur.

If you’re looking to learn more about troubleshooting or air compressor maintenance in general, there are many resources available online or through industry experts. Remember, taking care of your compressor now will save you both time and money down the road.