Blog

SMACO Portable Air Compressor

Introducing

Is it time for you to get your own electric air compressor?

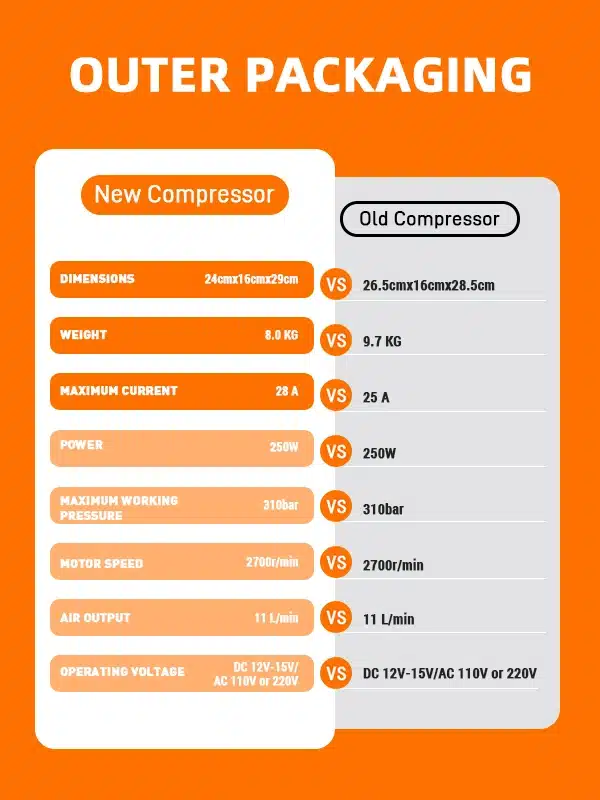

SMACO has refurbished and upgraded the SMACO Portable Air Compressor from the inside out by gathering consumer voices. This article provides a detailed comparison between the old and the new air compressor, introducing updates in four areas: basic parameters, internal/external accessories, outer packaging, and cleaning and maintenance.

SMACO Portable Air Compressor Basic Parameters

According to the comparison of the basic parameters of the two versions of air compressors, it can be seen that the new version of the air compressor is more compact and lightweight, and can accept and carry more current.

Air Compressor Internal/External Accessories

-

Internal fittings

-

One-Way Valve Gasket: The high temperature First-level piston ring has been replaced with a One-Way Valve Gasket and a High-Pressure Cylinder Seal Ring for easy cleaning.

-

Pressure Relief Valve Seal: The Pressure Relief Valve Seal is replaced from the side to the bottom, and the position of the Drainage outlet is changed to facilitate drainage during inflation.

-

Toolkit: Along with the update of accessories, the toolkit has been replaced with a combination that is more suitable for the new version of portable air compressor.

-

External accessories

-

Thermovent: In addition to the two Thermovent on the side, we added a back Thermovent to improve the heat dissipation efficiency and reduce the risk of high temperature.

-

Power switch: We have modified the original setting. The power switch of the old air compressor would light up when inflating. Currently, the compressor operation switch no longer has a light display.

-

Drainage outlet: The position is changed from the front to the bottom to prevent the oil and water secretions from being sprayed everywhere. If you operate indoors, you can prepare a dustproof mat or water-absorbing mat at the bottom in advance.

Air Compressor Packaging

We have often received feedback from users that the compressors they received just malfunctioned or had parts that were obviously falling off. Excluding privacy issues caused by violent couriers, we found that the biggest possibility was packaging issues, which resulted in the carrier being unable to distinguish the front and back of the package during transportation, and the internal transportation protection may not be in place. So our design and product development team immediately began upgrading and optimizing product packaging to ensure product quality and performance.

So, we added ↑↑, Hold it lightly and other reminders on the original outermost packaging, as well as the design of the handles on both sides of the carton to make it easier to pick up.

After the adjustment, no user reported any problems with the compressor.

Maintenance

1、 Replacing the explosion-proof diaphragm

Replacing the explosion-proof diaphragm is the same for new and old versions, please refer to the following video or instruction manual for specific operation.

-

Clean a cylinder

Due to the change of the One-Way Valve Gasket, the steps of cleaning a cylinder save the removal of the cylinder and the high temperature, which makes the cleaning more simple and easy to operate. For specific operation, please refer to the following video or instruction manual

Operation guide

Do you still think that owning your own electric compressor is difficult to use or maintain? Get your own high-voltage electric inflator, inflate it anytime and anywhere, complete the inflating in 4 steps, and go.

Conclusion

Through continuous updating and iteration, the SMACO HEAP 1 Portable High-Pressure 4500Psi Electric Air Compressor now offers significant advances in efficiency, durability, and overall performance, whether it’s for applications such as air cylinders, air guns, or inflatable boats.

What are your thoughts on upgrading air compressors? Share your experiences in the comments below!